| Laboratory: | Oak Ridge National Laboratory (ORNL) |

| Capability Expert: | Gabriel Veith |

| Capability Details: | |

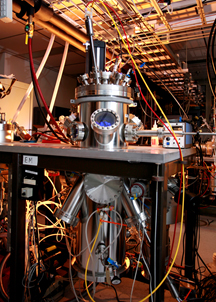

| Title: | Sputter deposition of PGM-free catalysts by vapor deposition |

| Class: | Processing/Manufacturing |

| Description: | Two sputter deposition chambers with the ability to deposit PGM-free catalysts by sputtering. Samples can be grown in thin film form or as conformally deposited supported nanoparticles on any vacuum stable support powder. Equipment is available for multiple material deposition, deposition gases, and target fabrication. Suitable deposition materials include magnetic, nonmagnetic and ceramic compounds. Reactive sputtering is available to form oxides, nitrides, carbides, etc. |

| Capability Bounds: | Samples are limited to a volume of 100 cm3. |

| Unique Aspects: | This capability is developed to vapor deposit supported metal nanoparticle catalysts on any vacuum stable support material. Materials that have been investigated include supported metals (e.g. Au, Pt, Ni, Co) and reactively deposited oxides and nitrides; these are both unique aspects that distinguish this capability within the national labs. |

| Availability: | Access through standard budgetary agreements and negotiated terms. |

| References: |

G.M. Veith, A.R. Lupini, L. Baggetto, J.F. Browning, J.K. Keum, A. Villa, L. Prati, A.B. Papandrew, G.A. Goenaga, D.R. Mullins, S.E. Bullock, and N.J. Dudney, “Evidence for the Formation of Nitrogen-rich Platinum and Palladium Nitride Nanoparticles,” Chemistry of Materials 25[24] 4936 (2013). G.M. Veith, A.R. Lupini, S. Rashkeev, S.J. Pennycook, D.R. Mullins, V. Schwartz, C.A. Bridges, and N.J. Dudney, “Thermal Stability and Catalytic Activity of Gold Nanoparticles Supported on Silica,” Journal of Catalysis 262[1] 92 (2009). G.M. Veith, A.R. Lupini, and N.J. Dudney, “Role of pH in the Formation of Structurally Stable and Catalytically Active TiO2-supported Gold Catalysts,” Journal of Physical Chemistry C 113[1] 269 (2009). |

| Benefit: | This equipment can rapidly synthesize complex materials in nanomaterial form on any vacuum stable support material. Materials include metal oxides, carbides and nitrides, which cannot be easily prepared from solutions. This process is scalable to large volumes (tens of gallons) of materials. In addition, facility is in close proximity to ORNL’s Microscopy Characterization Center (MCC) to enable rapid characterization of the materials grown via this capability. |

ORNL’s sputter deposition system.