| Laboratory: | Argonne National Laboratory |

| Capability Expert(s): | Ted Krause, Magali Ferrandon, and Debbie Myers |

| Capability Details: | |

| Title: | High-throughput characterization of PGM-free catalysts, catalyst precursors, catalyst-ionomer inks, and electrodes |

| Class: | Characterization & Testing |

| Description: | Argonne’s High-Throughput Research Laboratory (HTRL) has analytical equipment designed to operate in concert with the robotic platforms used for synthesis of materials and using high-throughput methodology. This equipment can be used for characterization of PGM-free catalyst precursors, catalyst synthesis solutions, PGM-free catalysts, catalyst-ionomer inks, off-gas generated during pyrolysis, and electrode layers by the following techniques:

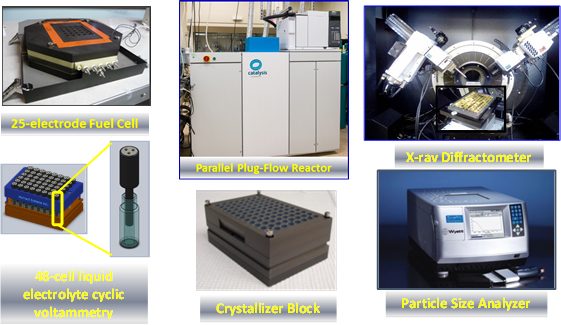

The HTRL also has a sixteen parallel plug flow reactor apparatus which can be heated to 900°C under a variety of gas and liquid atmospheres and pressurized up to 1160 psig, and is equipped with real-time analysis of the gas phase effluent from each of the sixteen flows. This apparatus is useful for the high-throughput pyrolysis and analysis of sixteen catalyst precursor compositions simultaneously for mechanistic studies of the catalyst formation process. An optimization Sampling Reactor (OSR), which consists of 8 parallel liquid batch reactors, is also available on a deck of the automation platform. This apparatus allows carrying out various reactions of polymerizations and sampling under reaction conditions to provide kinetic data. Each reactor can have independent temperatures (up to 200°C) and pressures (up to 400°C). This capability also includes an apparatus for simultaneous performance testing and characterization of twenty-five electrodes in a membrane-electrode assembly (NuVant System Incorporated’s Array Fuel Cell). Each electrode is 1.27 cm2 in active area, thus requiring minimal catalyst material. The twenty-five electrode cell will enable the testing of not only catalytic activity and stability of materials in the fuel cell environment, but also performance testing at high current densities in air to explore the effects of parameters like the ionomer-to-carbon ratio in inks, ink solvent, and loading on electrode performance. |

| Capability Bounds: | The HTRL has many pieces of analytical equipment configured for high-throughput analyses: DLS (96 well plate, 5-20 s per sample, particle size ranging from 0.5 to 1,000 nm in solution, temperature control ranging from 4 to 70°C, and imaging capability for solubility); gas and liquid chromatography with various detectors (TCD, MS, FID) and autosamplers; XRD (96 powders via a programmable moving stage). For preparing powders onto the 96 well substrate for XRD analyses, suspensions can be aliquoted into a 96 well crystallizer block, then evaporated in a heated vacuum centrifuge. |

| Unique Aspects: | The unique aspect of the analytical instrumentation in Argonne’s HTRL is that it is designed to work seamlessly with the robotic platforms. The 48-cell cyclic voltammetry set-up was developed in a collaboration between Argonne and NuVant and is exclusively available at Argonne. The HTRL researchers have broad expertise in utilizing the unique instrumentation in the areas of catalysis, energy storage, fuel cells, artificial photosynthesis, gas separation and storage, and nanoscale materials. |

| Availability: | The high-throughput research laboratory is a capability within Argonne’s Chemical Sciences and Engineering Division and is available as a resource both within Argonne and to collaborators from outside organizations. |

| References: |

“High-Throughput Synthesis, ORR Activity Modeling, and Testing of non-PGM PEMFC Cathode Catalysts,” Deborah J. Myers (Primary Contact), Xiaoping Wang, Sheldon Lee, Magali Ferrandon, Nancy N. Kariuki, and Theodore Krause, FY 2015 Progress Report for the Hydrogen and Fuel Cell Technologies Office, U.S. Department of Energy. |

| Benefit: | The combinatorial and/or high-throughput characterization of materials coupled with the combinatorial and/or high-throughput synthesis of materials can accelerate the identification and development of new PGM-free electrocatalysts with targeted ORR activities and stability. The exploration of variable space can also accelerate electrode fabrication and performance testing at relevant current densities. Besides accelerating the testing of materials and electrode structures in the fuel cell environment, the 25-electrode cell also has the advantage of requiring minimal quantities of catalyst for each electrode since each electrode has an active area of only 1.27 cm2. |