| Laboratory: | National Renewable Energy Laboratory (NREL) |

| Capability Expert: | Guido Bender |

| Capability Details: | |

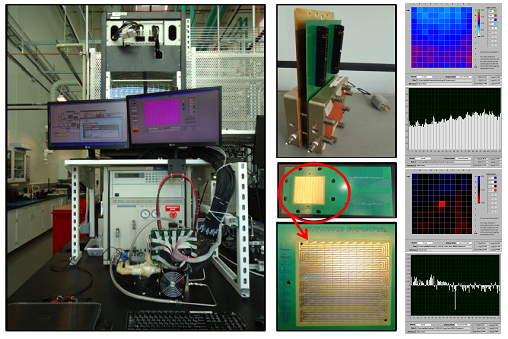

| Title: | Spatial performance evaluation using a segmented cell with a 121 multichannel electrical load |

| Class: | Characterization |

| Description: |

High-throughput in-situ testing of electrode layers with gradient component composition, component distribution, and/or layer properties as resulting from high throughput and combinatorial catalyst development requires specialized diagnostic equipment. Operating a standard segmented cell system comes to mind for such an application. A typical segmented cell system allows for the spatial observation of the natural current and voltage distribution of a fuel cell. The spatial nature of the data originates from changing operating conditions along the flow field due to water production, MEA properties, GDL properties, and flow-field and gas manifold design. These are all effects that need to be suppressed to create meaningful results for high throughput or combinatorial cells, which should focus solely on the performance of the item under investigation, such as a changing catalyst or catalyst layer composition. NREL successfully operates a segmented cell system for in situ performance characterization of PEMFCs to establish manufacturing tolerances with respect to coating irregularities in PEMFC electrodes. The high-resolution system features 121 segments within a 50 cm2 total cell electrode area and individually controlled electronic load units. The existing system provides the ideal framework for developing a system that enables high-throughput combinatorial electrode research, because it allows interrogation of each area at identical operating conditions. The current system features a maximum current capacity of 1 A / segment, which translates to 2.5 A/cm2 maximum current density for the existing PEMFC hardware. It further features scriptable data acquisition and visualization software, including comparative representation to a reference or standard sample. The system capability is complemented by 15 years of exclusive experience in spatial PEMFC diagnostic equipment development and testing, including performance and durability testing, round-robin and benchmark testing for RDEs and MEAs across laboratories and equipment verification and calibration. |

| Capability Bounds: | NREL’s segmented cell system is currently limited to voltage-current curve characterization in oxygen or air. As mentioned previously, one typical characteristic of segmented cell diagnostic systems is the inherent change of operating conditions along the flow-field during operation of a PEMFC due to fuel and oxidant consumption and reaction water production. Such spatial operating conditions lead to spatially varying performances even of identical catalyst materials. The segmented cell features 121 segments within a 50 cm2 total cell electrode area, and a maximum current density of 2.5 A/cm2. |

| Unique Aspects: | Compared to other segmented cell systems operated at DOE laboratories, NREL’s segmented cell system is a very-high-resolution segmented cell with 121 segments distributed over a 50 cm2 cell area. The system also differentiates itself from other segmented cell system by using a measurement strategy that is based on individually controllable electronic load units. This is specifically useful for combinatorial electrode research. Furthermore, the system features custom designed one-of-a-kind data visualization software. This software is capable of visualizing and comparing spatial sample data sets with spatial reference data sets. |

| Availability: | The equipment is located in the ESIF user facility and currently well utilized for DOE Manufacturing Project. The system needs to be further developed for combinatorial work. |

| References: | G. Bender, W. Felt, M. Ulsh, “The Spatial Performance Effect of Electrode Defects in PEMFC,” ECS Fall Meeting, Honolulu, HI; October, 2012. |

| Benefit: | The NREL segmented cell system, with its existing unique capabilities, can be leveraged to characterize H2/O2 and H2/air performance of 50 cm2 high-throughput or combinatorial MEA samples. With the existing system, 121 combinatorial samples within one MEA can be compared area by area to a reference sample. Thus, the system allows for about four times the throughput of the segmented system currently operating at ANL. Furthermore, the segmented system’s software is able to directly compare the data output of the combinatorial sample to reference baseline samples. This will enable ElectroCat to perform very rapid screening of any combination of catalyst material of interest and accelerate the development of PGM-free catalysts for transportation and stationary applications. Additional benefits could be developed by adding electrochemical characterization capabilities. |

Left: Segmented cell system with 121 load and voltage sense cables connected. Center: Details of hardware and quadruple channel segmented flow-field. Right: Examples of current density distribution data visualized by intensity plots and bar graphs. Right Top: MEA operated at 32%/32% RH. Right Bottom: Electrode with 0.5 cm2 coating defect compared differentially to pristine MEA.