| Laboratory: | Los Alamos National Laboratory (LANL) |

| Capability Expert(s): | Dusan Spernjak and Rangachary Mukundan |

| Capability Details: | |

| Title: | Advanced fuel cell characterization techniques |

| Class: | Characterization |

| Description: |

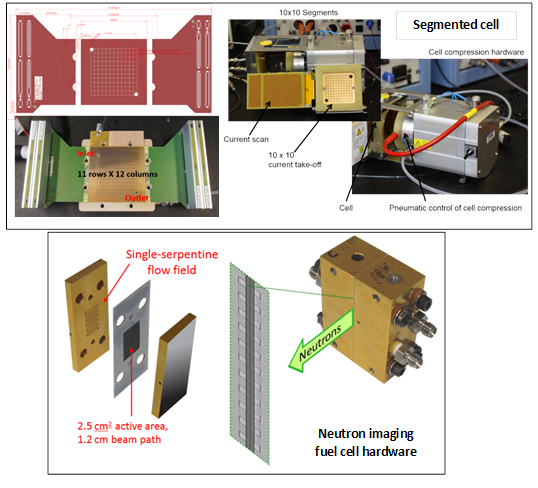

Advanced fuel cell diagnostic tools are extensively used for a number of different studies of PGM-free electrodes including mass transport optimization, water and thermal management, and flow field design and validation. LANL possesses advanced fuel cell characterization hardware, designed on site to perform these studies. The hardware includes (a) two high-resolution segmented cells for simultaneous measurements of current and temperature distributions and (b) LANL-upgraded high-resolution neutron imaging fuel cell hardware. The segmented cell hardware is composed of 132 segments for current distribution and 66 segments for temperature distribution, allowing for concurrent measurements of the current and temperature. Improved temperature control in the segmented cell is obtained by utilizing LANL end-plates with liquid cooling for better control at low operating temperatures and relatively high currents. The hardware is designed to fit into standard LANL fuel cell test hardware and operates at two current ranges: high current range for fuel cell operation and low current range for cyclic voltammetry and other electrochemical techniques. The segmented cell is operated using a multi-channel potentiostat equipped with 10 channels. Current boosters allow operation at a range of up to 10 A per channel. LANL has also designed several generations of fuel cell assemblies dedicated to water management studies using NIST’s neutron source. Among other modifications, LANL’s latest re-design of the neutron imaging hardware consists of the addition of an Invar holder to minimize movements due to thermal expansion, parallel channels for differential cell studies, single-serpentine cells for GDL and catalyst studies, and metal-foam flow fields for membrane studies (developed in collaboration with Nuvera). |

| Capability Bounds: | The segmented cell is limited to 132 segments for a total combined active area of 77 cm2. Neutron imaging fuel cell hardware is limited to a 2.5 cm2 active area and a 1.2 cm beam path. |

| Unique Aspects: | Measurements of individual cell segments provide essential information about the spatial distribution of performance losses and allows for the determination whether improvements can be achieved in either the mass transport and/or kinetic regions. Various designs of the neutron imaging fuel cell hardware permit targeting the components of a PGM-free MEA for better understanding which specific regions are in need of improvements. |

| Availability: | Segmented cells and neutron imaging fuel cell hardware are part of the LANL fuel cell program and are available to Electrocat. |

| References: |

J. Dillet, D. Spernjak, A. Lamibrac, G. Maranzana, and R. Mukundan, “Impact of flow rates and electrode specifications on degradations during repeated startups and shutdowns in polymer-electrolyte membrane fuel cells,” J. Power Sources, 250, 68 (2014). D. Spernjak, J. Fairweather, R. Mukundan, T. Rockward, and R. Borup, “Influence of the microporous layer on carbon corrosion in the catalyst layer of a polymer electrolyte membrane fuel cell,” J. Power Sources, 214, 386 (2012). R. Mukundan and R. Borup, “Visualising Liquid Water in PEM Fuel Cells Using Neutron Imaging,” Fuel Cells, 5, 499 (2009). |

| Benefit: | Characterization of PGM-free electrodes using advanced fuel cell characterization techniques, such as the ones described here, are essential for the development of high-performance PGM-free fuel cell systems. |