| Laboratory: | Oak Ridge National Laboratory (ORNL) |

| Capability Expert: | Karren L. More |

| Capability Details: | |

| Title: | In situ scanning transmission electron microscopy (STEM) methods |

| Class: | Characterization |

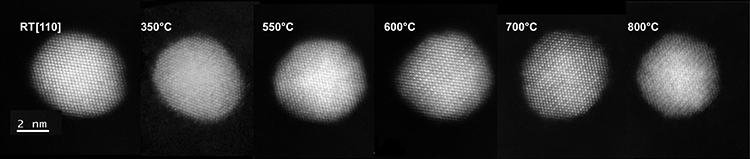

| Description: | The ability to study the dynamic behavior of PGM-free catalysts under relevant operating and/or synthesis conditions (e.g., temperature, pressure, potential cycling, and environment) can provide unprecedented nanometer-level insight regarding morphological and compositional changes that contribute to performance degradation. High-resolution images and spectroscopic data captured in real-time during in situ transmission electron microscopy (TEM) and aberration-corrected scanning transmission electron microscopy (STEM) experiments can be used to simulate and understand the effects of multiple variables on reaction kinetics during synthesis and environmental operation. Such data are acquired using specialized in situ liquid, gas, or heating holders that are designed to conduct studies under relevant fuel cell conditions. Knowledge gained from systematic in situ STEM observations can provide a mechanistic understanding of PGM-free catalyst durability and degradation behavior specifically related to changes in material surfaces, nanoparticle morphologies, porosity creation/collapse, elemental redistribution, and other factors, and can ultimately aid in producing highly stable PGM-free materials. |

| Capability Bounds: | NA |

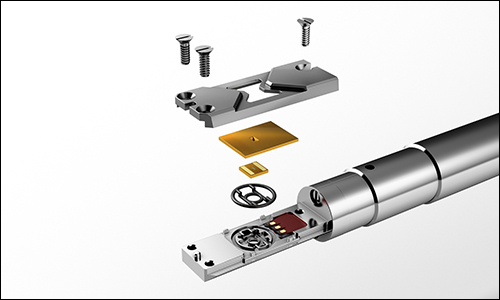

| Unique Aspects: | ORNL has several unique commercial holders that have been designed for conducting in situ liquid electrochemistry, in situ gas-flow reactions, and in situ heating. The capabilities for each are described in greater detail below:

Experiments can be designed with ORNL staff aimed towards studying evolving structural and chemical characteristics of PGM-free catalysts under relevant or simulated operating conditions. |

| Availability: | Instruments and holders in ORNL’s Materials Characterization Center (MCC) are available for partnership with industry through Strategic Partnership Projects (SPP), cooperative research and development agreements (CRADAs) via full-cost recovery (hourly fee), and direct project collaborations to facilitate new materials discovery and understanding; instruments in ORNL’s Center for Nanophase Materials Sciences (CNMS – a U.S. DOE Office of Science User Facility) are accessible through a peer-reviewed proposal process (no cost if results are publishable and full-cost recovery if data is proprietary). All instruments in the MCC and CNMS are available for conducting in situ characterization of PGM-free catalysts and MEAs. |

| References: |

R.L. Sacci, J.M. Black, N. Balke, N.J. Dudney, K.L. More, and R.R. Unocic, “Nanoscale Imaging of Fundamental Li Battery Chemistry: Solid Electrolyte Interphase Formation and Preferential Growth of Li Metal Nanoclusters,” Nano Letters 15 2011 (2015). L.F. Allard, S.H. Overbury, W.C. Bigelow, M.B. Katz, D.P. Nackashi, and J. Damiano, “Novel MEMS-based Gas-Cell/Reaction Heating Specimen Holder Provides Advanced Imaging Capabilities for In Situ Reaction Studies,” Microscopy & Microanalysis 18[4] 656 (2012). M. Chi, C. Wang, Y.K. Lei, G.F. Wang, D.G. Li, K.L. More, A. Lupini, L.F. Allard, N.M. Markovic, and V.R. Stamenkovic, “Surface Faceting and Elemental Diffusion Behaviour at Atomic Scale for Alloy Nanoparticles During In Situ Annealing,” Nature Communications 6 8925 (2015). |

| Benefit: | ORNL’s unique in situ STEM capabilities provide controllable methods to expose PGM-free materials to relevant fuel cell synthesis or operating conditions to understand temperature, pressure, and environmental effects on catalyst durability. |

(a) Schematic of the closed-cell design of liquid/gas flow cell.

(b) Evolution of single Pt-alloy catalyst nanoparticle during in situ heating.3